|

|

|

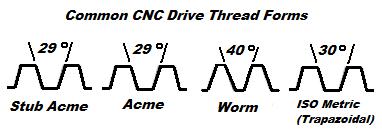

Why the Acme thread form is used for lead screwsThe acme thread form is most often associated with lead screws or CNC drive systems, and for good reason. These threads are broader, stronger, and squarer than standard V-shaped threads. This makes them ideal for power transmission and carrying loads. However, there are other thread forms used in CNC drive systems as well. Reference the image below.  The acme lead screw is probable the most widely used in the united states because of the availability. Also, the availability of acme nuts is far more readily available than worm screws. ISO Metric Trapezoidal is often found on European CNC systems. Some of the mini lathes use this thread form.

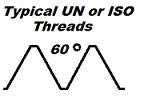

Standard threads have been used in hobby CNC routers with some success, but it is not recommended for machines larger than about 12 inches or so. It is also not recommended for machines designed for large loads. In any case it is usually worth the investment to buy at least general purpose or stub acme thread lead screws, but centralizing or higher grade acme screws are always recommended. If typical threaded rod is used, be sure to use an oil-based grease to diminish friction and galling. Overall acme screws have much better wear properties, load capabilities, and tolerances, than standard threaded rod. Since the threads are thicker and wider, they operate better in environments with dirt and debris as well. Continue to: Acme Lead Screw Straightness and Accuracy Go to: Acme Terminology |

The Builder's Guide

Calculators

CNC Controllers

|

|

|

[?] Subscribe To This Site

Page Missing?Please bare with us as we upload pages. The website is still under contruction and new content is being added. To see the most recent pages, visit the website blog. Thank you! |

||

|

|

Homepage |

Buyer's Guide |

Builder's Guide |

Contact Us|

© Copyright 2007-2011. |

||

|

|

||